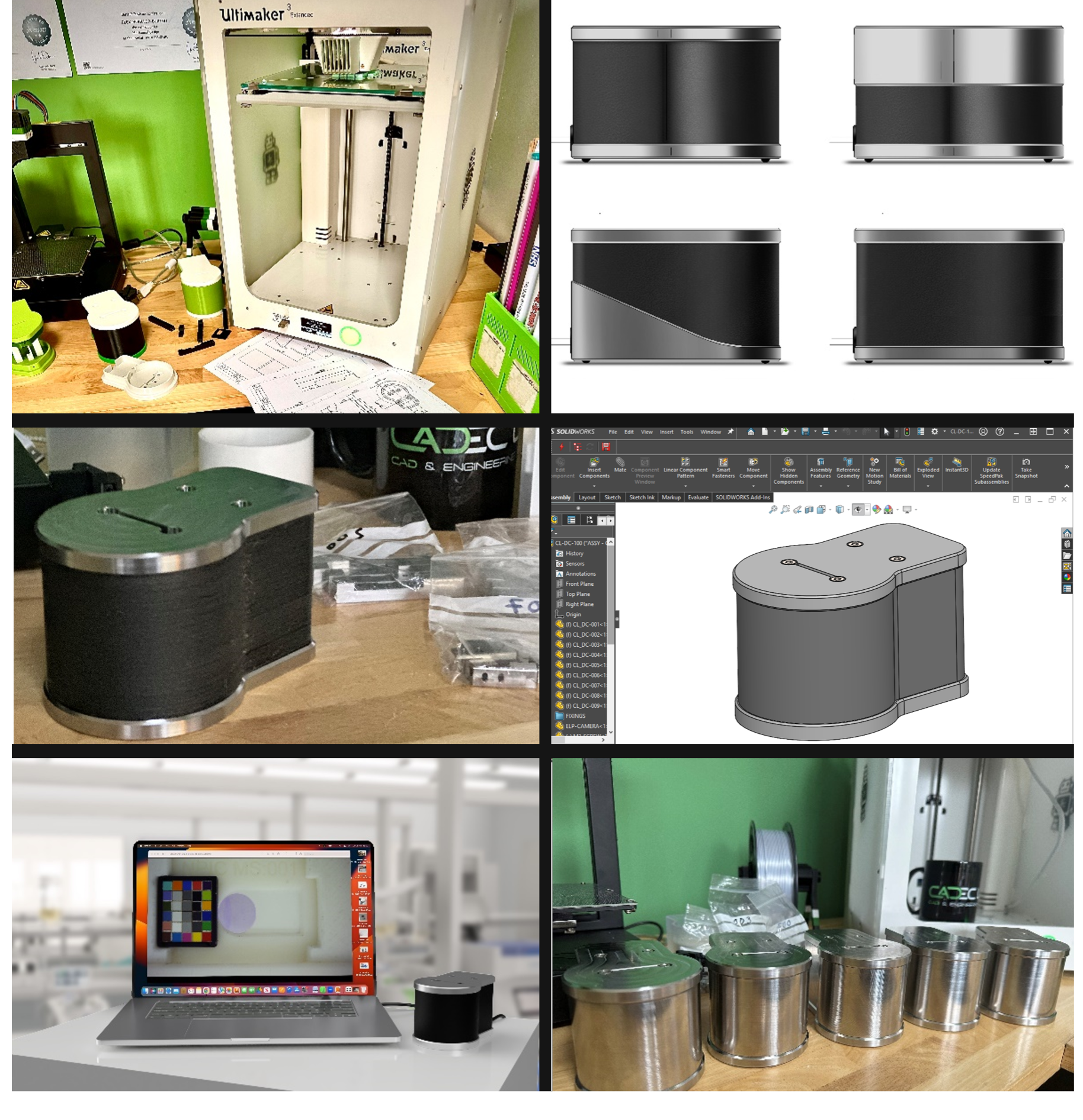

Product Development – Mini Scanner

Approached by members of the NPIC team to produce qty of 10 Off prototypes within a 4-week timescale.

Objective

Review initial provided design and suggest modifications where necessary to ensure manufacturability of parts.

Services provided :

- Design Critique of initial design proposal.

- CAD Modelling / 2D Drawing Creation..

- Provided design record and documentation pack.

- Production of 3D Printed sample parts prior to machining of final parts to sign off fit and form.

- Provided 10 OFF Prototype Parts suitable for field trials, fully managed sub supplier/machinist.