Fixture Design :

At CADEC Limited, we provide a comprehensive range of fixture design services aimed at improving manufacturing efficiency, precision, and repeatability. Our expertise spans the development of high-quality custom tooling, jigs, gauges, and fixtures that support diverse production and assembly operations. By leveraging advanced CAD tools and years of practical experience, we ensure each design delivers robust functionality, seamless integration, and long-term reliability.

Key Features of Our Fixture Design Services

- Custom Fixture Development:

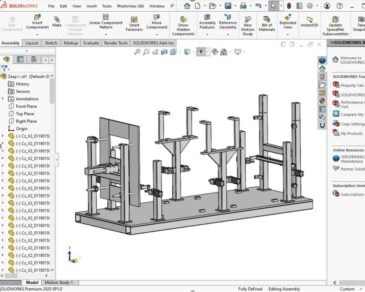

We design tailored fixtures to meet specific client requirements, whether for assembly, machining, inspection, welding, or testing. Our solutions enhance accuracy and streamline production workflows, addressing even the most complex operational challenges. - 3D CAD Modelling and Visualisation:

Using advanced CAD software such as SolidWorks and Catia V5, we create detailed parametric models and virtual simulations. This enables clients to review and approve designs confidently before physical production begins, reducing risk and ensuring alignment with project objectives. - Precision Engineering with GD&T:

Our designs incorporate Geometric Dimensioning and Tolerancing (GD&T) to ensure fixtures achieve precise alignment, positioning, and repeatable performance. This ensures critical tolerances are met, contributing to superior product quality and consistency. - Material Selection Expertise:

Our extensive knowledge of material properties allows us to select the most suitable materials for each fixture. Whether working with steel, aluminium, composites, or advanced alloys, we ensure durability and cost-efficiency tailored to operational demands. - Prototyping and Validation:

Before full-scale production, we produce prototypes to test the functionality and accuracy of fixtures. Prototypes undergo rigorous validation to ensure they meet operational, safety, and ergonomic requirements, reducing downtime and unforeseen production issues. - Optimisation for Manufacturing Processes:

We design fixtures with manufacturability and usability in mind, incorporating features that simplify setup, reduce cycle times, and minimise operator error. Our designs often include quick-release mechanisms, ergonomic adjustments, and modular components for flexibility. - Tooling and Assembly Integration:

Our experience in integrating fixtures with existing tooling systems ensures seamless compatibility. This includes designing for robotic systems, CNC machines, or manual operations to meet specific production needs.

Applications of Our Fixture Designs

- Machining Fixtures: Solutions designed for milling, turning, grinding, and other precision machining tasks, ensuring stability and accuracy.

- Inspection Fixtures: Tools that enable precise measurement and quality checks, ensuring compliance with dimensional and geometric tolerances.

- Welding and Fabrication Fixtures: Configurations that stabilise components during welding or fabrication, optimising safety and precision.

- Assembly Fixtures: Customised solutions for positioning and securing components during complex assembly processes.

- Testing Fixtures: Designs that support load, stress, or functional testing of products to ensure performance under real-world conditions.

Why Choose CADEC Limited?

- Extensive Industry Experience:

With years of experience across industries such as automotive, aerospace, medical devices, and industrial manufacturing, we understand the specific needs and challenges of diverse sectors. Our portfolio includes work for leading brands, showcasing our ability to deliver at the highest levels. - Innovative Problem-Solving:

We pride ourselves on tackling complex challenges with creative, engineered solutions that deliver measurable results. From one-off prototypes to high-volume production fixtures, we adapt to meet client needs efficiently. - End-to-End Support:

We guide clients through every stage of fixture design, from concept development and material selection to prototyping, testing, and final production. Our collaborative approach ensures the final product aligns perfectly with operational goals. - Advanced Software and Tools:

Our team is proficient in the latest CAD and simulation technologies, enabling us to design and analyse fixtures for strength, durability, and performance under real-world conditions. - Commitment to Quality:

We follow rigorous quality assurance processes, ensuring every fixture meets exacting standards for precision, safety, and longevity.

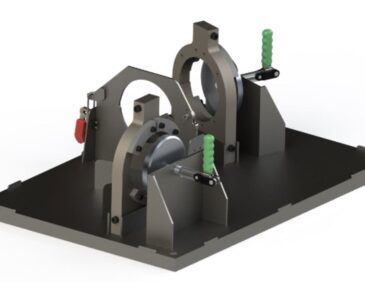

Examples of Our Work

Our experience includes the design of jigs and fixtures for complex projects such as:

- EV battery assembly fixtures for Nyobolt, incorporating modular components and ergonomic adjustments.

- Welding fixtures for automotive body structures, ensuring consistent alignment during fabrication.

- Inspection fixtures for high-performance aerospace components, achieving critical tolerance validation.