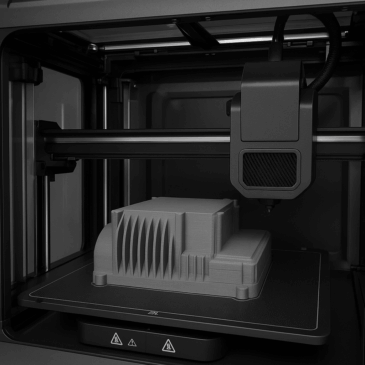

3D Printing

3D printing, also known as additive manufacturing, is a cutting-edge process that builds objects layer by layer directly from digital models (STL Files) . This technology unlocks design possibilities and enables the creation of complex geometries that are impossible to achieve using traditional manufacturing methods.

Applications of 3D Printing

- Prototyping: Rapidly create and test design concepts, accelerating product development.

- Manufacturing: Ideal for low-volume production and fabricating intricate components for industries like aerospace, automotive, and healthcare.

- Medical: Produce customized implants, prosthetics, and anatomical models for surgical planning.

- Consumer Products: Design personalized items such as footwear, jewelry, and home décor.

Benefits of 3D Printing

- Design Freedom: Produce highly complex and customized designs without additional cost.

- Material Efficiency: Minimize waste by using only the material required for the part.

- Speed: Reduce time from concept to production, enhancing responsiveness to market needs.

- Cost-Effectiveness: Avoid expensive tooling, making it ideal for small production runs.

3D Printing Technologies We Offer

Fused Deposition Modeling (FDM)

- Description: FDM melts and extrudes thermoplastic filaments through a heated nozzle, depositing material layer by layer to create the object.

- Uses: Perfect for prototyping, educational models, and simple functional parts.

- Benefits:

- Affordable and accessible.

- Compatible with versatile materials such as PLA, ABS, and PETG.

- Suitable for creating durable prototypes and end-use components.

Stereolithography (SLA)

- Description: SLA uses a laser to cure liquid photopolymer resin into solid layers, achieving exceptional detail and smooth surface finishes.

- Uses: Ideal for dental applications, jewelry design, and intricate prototypes with fine details.

- Benefits:

- Exceptional precision and surface quality.

- Wide range of materials with varying properties.

- Perfect for applications requiring high detail and smooth aesthetics.

Selective Laser Sintering (SLS)

- Description: SLS employs a laser to sinter powdered materials, such as nylon, into solid structures without needing support structures.

- Uses: Designed for functional prototyping and small-to-medium production runs, especially for complex designs.

- Benefits:

- High strength and durability of parts.

- No need for support structures, enabling more complex geometries.

- Efficient for batch production by nesting multiple parts in a single build.

With the versatility of FDM, SLA, and SLS technologies, we provide tailored solutions for your project needs. Whether you’re creating prototypes, functional components, or intricate designs, 3D printing opens up a world of possibilities.